Cementitious vs Liquid Waterproofing

Cementitious vs Liquid Waterproofing – Which Performs Better in Middle East? Waterproofing failure in the Middle East is rarely a...

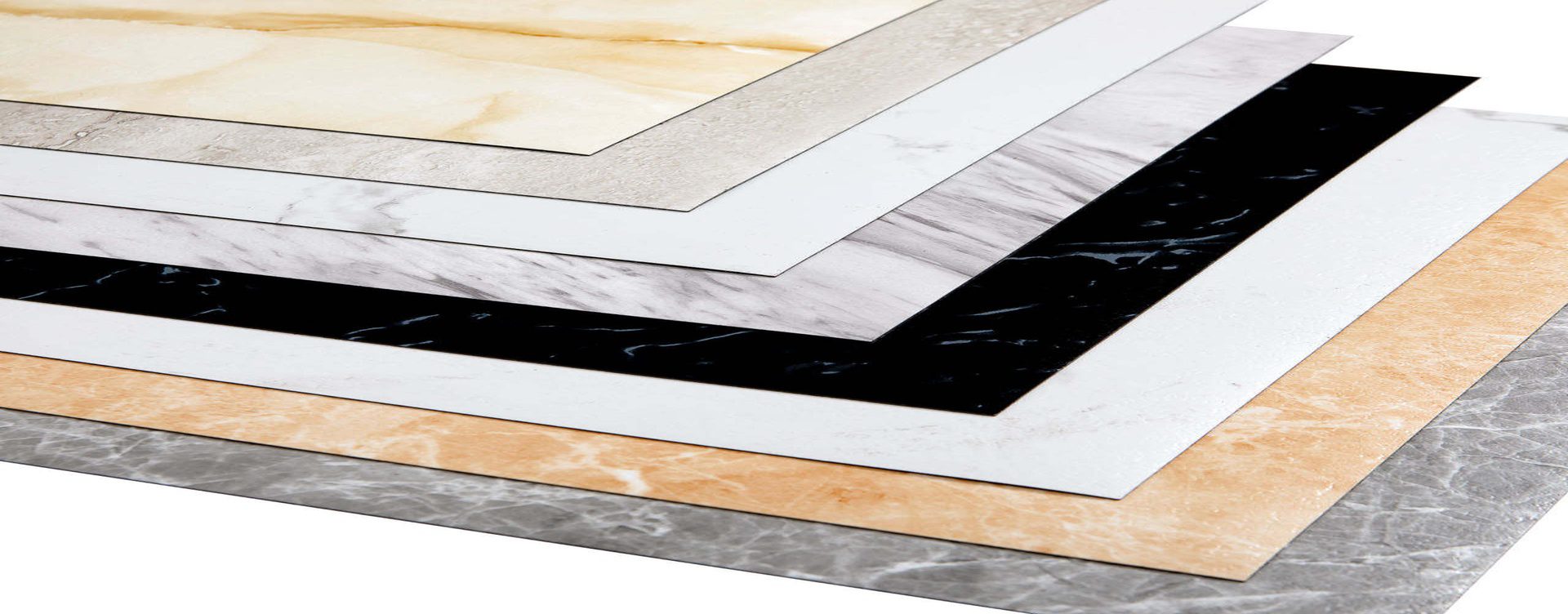

Across global furniture and interior markets, surface finish has become the new benchmark of quality. Buyers no longer ask only for colors or patterns — they ask for gloss index, texture depth, and coating uniformity.

As modular kitchens, retail displays, and office interiors scale worldwide, PVC panels have taken center stage. They combine the visual clarity of laminates,the moisture resistance of WPC, and the design flexibility of acrylic sheets — making them one of the fastest-growing categories in decorative trade.

According to industry data, the global PVC panel market exceeded USD 5.8 billion in 2024 and is on track to reach USD 8.6 billion by 2030.But for importers and distributors, the challenge lies not in demand — it lies in maintaining finish discipline across shipments.

That’s where GCC stands out — as a manufacturer, supplier, and exporter integrating finish control, labeling precision, and documentation reliability into every shipment of PVC decorative surfaces.

The Finish Defines the Brand

In export trade, high-gloss and matt are not marketing terms — they’re measurable surface performances.

High-gloss panels depend on UV-cured coatings that deliver reflectivity above 90 GU (gloss units), while matt panels rely on micro-embossed surfaces that diffuse light evenly between 10 – 25 GU.

Importers who supply modular manufacturers or retail projects know how easily inconsistency creeps in — a few microns more UV coating, a slightly different curing time, and a whole batch looks off under showroom lighting.

That’s why GCC treats every finish as a technical parameter, not an aesthetic promise. Each production run is tested for gloss index, surface adhesion, and thickness tolerance before dispatch.

| Finish Type | Gloss Units (GU) | Thickness | Surface Tech | Key Use |

|---|---|---|---|---|

| High-Gloss | ≥ 90 GU | 1.2 – 2.0 mm | UV-Coated / Acrylic | Kitchens · Retail Fronts |

| Matt | 10 – 25 GU | 1.0 – 1.8 mm | Embossed PVC | Walls · Commercial Spaces |

Each GCC shipment includes batch trace codes for reordering, gloss-variance reports (≤ ± 5 GU), and pre-dispatch photo verification — giving importers the confidence to promise repeatable results to their clients.

Read more about GCC’s PVC & Decorative Surface Range →

Where Importers Lose Margin — and How to Stop It ?

In the decorative-surface trade, losses rarely come from product cost. They come from process slippage.

A single missing HS code label, a minor scratch from loose packing, or incomplete documentation can hold a container at port for days.

GCC eliminates these gaps with systemized export discipline :

| Importer Pain Point | Typical Loss | How GCC Prevents It |

|---|---|---|

| Gloss deviation across batches | Rework / Client rejection | Controlled curing & ± 5 GU calibration |

| Friction marks during transit | Return claims | PE-film + interleaf paper + corner protection |

| Unclear or missing labels | Port delays | Multi-level export labeling (SKU · HS · PO · Consignee) |

| Documentation errors | Customs hold | 100 % verified docs before vessel cutoff |

| Mixed SKU confusion | Warehouse sorting delays | Digital packing maps & photo verification |

Every GCC shipment includes a digital inspection folder — test results, images, packing layout, and document set — sent to the importer before the bill of lading is issued.

Packaging & Labeling: Small Details, Major Returns

A panel’s surface may sell the product, but its labeling sells the shipment.

In many markets, missing details like “finish type” or “HS Code” trigger inspection or re-classification.

GCC’s multi-layer labeling system ensures transparency at every stage:

Labels are printed in multiple languages and positioned for quick scanning at customs. Combined with reinforced pallets and moisture barriers, GCC maintains a damage incidence below 0.5 % across shipments.

Sourcing PVC panels isn’t about finding suppliers who can match colors — it’s about finding exporters who can match consistency. Every gloss reflection and every matt texture must perform identically, shipment after shipment.

That’s what GCC delivers — export-grade finish quality, batch-level QC, and logistics precision built around importer realities, not manufacturer convenience.

When surfaces define impression, GCC ensures every panel delivers one — precision that ships on time./span>

Read more about GCC’s Laminates & Surface Division →

Resources :

https://www.metastatinsight.com/report/pvc-wall-panels-market

https://witopdecor.com/exporter-china-building-material-home-decoration-pvc-wall-panel/