Cementitious vs Liquid Waterproofing

Cementitious vs Liquid Waterproofing – Which Performs Better in Middle East? Waterproofing failure in the Middle East is rarely a...

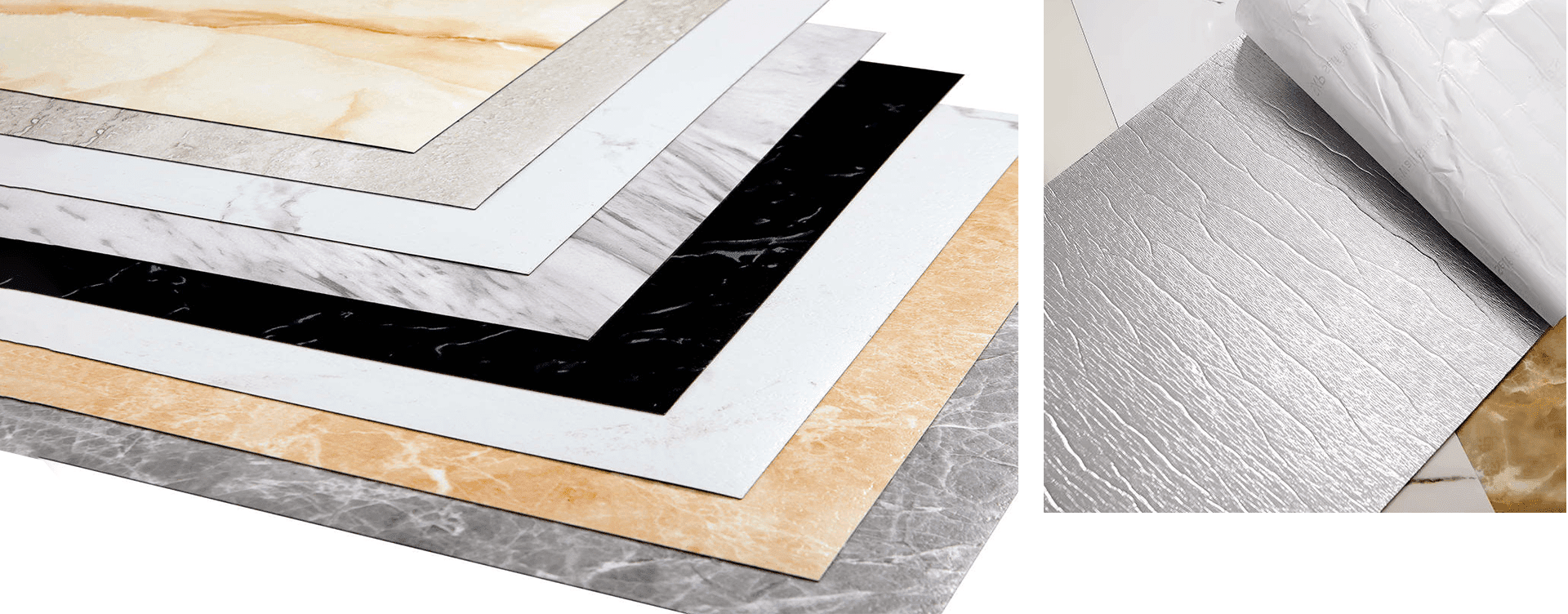

Across Europe’s interior and furniture markets, a quiet but clear shift is underway. Designers, builders, and procurement teams are moving away from reflective high-gloss panels toward textured and matt laminates that convey subtle luxury and natural realism. What began as a design trend has now become a trade reality – shaping how importers and distributors evaluate suppliers across Europe.

The European laminate industry, valued at USD 11.4 billion in 2024, is projected to cross USD 15 billion by 2030, growing at 5–6% CAGR. More than 60% of new imports in decorative surfaces now belong to the matt and textured category (Statista, EU Trade Data).

For importers, this transformation demands new discipline in sourcing: consistency, documentation accuracy, and process control have become as critical as price.

European Market Snapshot

From Germany and Italy’s luxury kitchens to Poland’s modular furniture production, textured laminates have become the new standard of modern European design.

Buyers now seek finishes that diffuse light evenly, resist fingerprints, and retain visual depth even after heavy usage.

| Region | Import Share (2024) | YoY Growth | Dominant Finish Type |

|---|---|---|---|

| Western Europe | 42% | +11% | Super Matt / Silky Texture |

| Northern Europe | 26% | +9% | Textured, Anti-Fingerprint |

| Eastern Europe | 18% | +7% | Soft Matt / Embossed Grain |

| Southern Europe | 14% | +8% | Natural Grain / Warm Matt |

Read More → Explore GCC’s High-Pressure Laminates (HPL)

The New Sourcing Equation

European buyers no longer chase low-cost suppliers; they look for exporters who guarantee finish repeatability. In textured laminates, every press plate and adhesive film must align perfectly to avoid surface distortion or light scatter.

Manufacturers with export-grade process discipline – including real-time gloss metering, in-line emboss calibration, and TDS-backed shipment proofing – now command the most repeat orders.

| Performance Metric | GCC Export Standard | EN / ISO Reference | Buyer Advantage |

|---|---|---|---|

| Gloss Value (Matt) | 8–15 GU | EN 438-2:2023 | Reduces glare & fingerprints |

| Texture Depth | 40–120 µm | ISO 2813 | Natural tactile finish |

| Abrasion Resistance | ≥ 350 cycles | DIN 68861-4 | Long service life |

| Scratch Hardness | ≥ 3H | ASTM D3363 | Lower complaint rate |

| Thickness Tolerance | ± 0.05 mm | ISO 4586 | Smooth fabrication |

| Color Match | ≥ 95% | In-house sync test | Uniform retail finish |

Global Import Dynamics

| Source Country | Average FOB (USD/m²) | Lead Time (Days) |

|---|---|---|

| China | 3.8 – 5.0 | 35 – 45 |

| Vietnam | 4.0 – 4.8 | 30 – 35 |

| India | 4.0 – 5.5 | 20 – 25 |

Importers now view India as a stable alternative sourcing base, capable of supplying matt, textured, and super matt finishes with European-standard test data and faster replenishment cycles.

GCC: The Process Behind the Precision

Read More → Explore GCC’s Furniture Hardware Range

GCC’s ecosystem advantage extends beyond laminates. Importers often consolidate shipments that include hardware, upholstery foam, or decorative foils, streamlining customs clearance and optimizing landed costs.

The Integrated Sourcing Advantage

| Category | Key Export Product | Internal Reference Link |

|---|---|---|

| Decorative Surfaces | PVC Laminates High-gloss & textured variants | PVC Laminates |

| Furniture Components | Edge Banding Perfect décor color match | Edge Banding |

| Upholstery | HR Foam Density-calibrated comfort foam | HR Foam |

Read More → Explore GCC’s PVC Laminates Collection

By consolidating multiple product lines within one exporter, importers reduce transit handling, documentation duplication, and freight fragmentation – achieving greater control over cost and timeline.

The GCC Edge for European Buyers

GCC’s systemized approach – from batch calibration and container photography to digital documentation – ensures that importers receive not just compliant products but predictable performance across all SKUs.

As Europe continues its design shift toward matt and textured surfaces, India’s manufacturing discipline and GCC’s export infrastructure together represent the new definition of sourcing confidence.

Explore GCC’s Complete Decorative Laminates Collection – export-grade finishes engineered for performance, consistency, and global trade efficiency.

References & Sources