Cementitious vs Liquid Waterproofing

Cementitious vs Liquid Waterproofing – Which Performs Better in Middle East? Waterproofing failure in the Middle East is rarely a...

Why Importers Are Rethinking Traditional Wooden Doors ?

For decades, wooden doors dominated residential and commercial interiors. Today, however, importers and distributors are actively moving away from solid wood doors – not because of declining demand, but because of cost volatility, performance risk, and after-sales exposure.

Global construction materials data shows that engineered door materials (WPC, PVC, composite-core doors) are growing at 7–9% CAGR, while traditional solid wood doors are growing at less than 3% annually, largely restricted to premium and niche applications.

This divergence is especially pronounced across Africa, the Middle East, and Southeast Asia, where high humidity, termite exposure, and large-scale housing projects make wooden doors increasingly impractical for mass deployment.

GCC supports this market shift by exporting premium WPC doors that are 100% waterproof, termite-proof, dimensionally stable, and design-flexible – allowing importers to transition away from wood without introducing new supply risks.

Market Data: The Structural Shift from Wood to WPC

| Metric | Wooden Doors | WPC Doors |

|---|---|---|

| Average material price volatility (YoY) | 15–25% | 5–8% |

| Moisture-related complaints | High | Negligible |

| Termite / insect damage risk | High | Nil |

| Maintenance requirement | Regular polishing & repainting | Near-zero |

| Suitability for humid markets | Limited | Excellent |

Industry estimates indicate that over 60% of new residential door installations in humid or coastal regions now use WPC or composite doors instead of solid wood.

Why Wooden Doors Are Becoming Risky for Importers ?

| Common Issue with Wooden Doors | Trade Impact |

|---|---|

| Timber price swings | Unstable landed cost |

| Moisture absorption | Warping and swelling |

| Termite attacks | Replacement and warranty claims |

| Natural grain variation | Inconsistent batches |

| Polishing & repainting | Higher end-user dissatisfaction |

From an importer’s perspective, even a 3–5% claim rate on doors can wipe out margins, particularly in wholesale and project distribution models.

What Makes WPC Doors the Preferred Alternative ?

WPC doors are manufactured by blending wood fibre with polymer resins – delivering the visual appeal of wood with industrial-grade consistency and durability.

Performance Comparison: WPC vs Wooden Doors

| Parameter | Wooden Doors | WPC Doors (Export Grade) |

|---|---|---|

| Water absorption | 8–12% | <1% (100% waterproof) |

| Dimensional stability | Low | High |

| Termite resistance | No | Yes (100% termite-proof) |

| Typical lifespan | 7–10 years | 15–20 years |

| Maintenance cost | High | Minimal |

In addition, WPC doors exhibit zero bacterial growth, faster installation cycles, and eco- conscious material usage, reducing dependence on natural timber while maintaining a premium finish.

Typical WPC Door Specifications Importers Demand

Standardization is one of the biggest reasons WPC doors scale efficiently in export markets.

| Specification | Common Export Standard |

|---|---|

| Thickness | 25 mm / 30 mm |

| Width | 27", 30", 33", 36", 39" |

| Height | 78", 81", 84", 96" |

| Core | Solid WPC |

| Surface | Wood grain / textured / routed / digital |

| Frames | Single & double rebate (32×75 mm to 65×130 mm) |

Read More About GCC’s Laminates Product Range

These specifications cover 85%+ of residential and commercial door demand, enabling importers to stock fewer SKUs while servicing more projects.

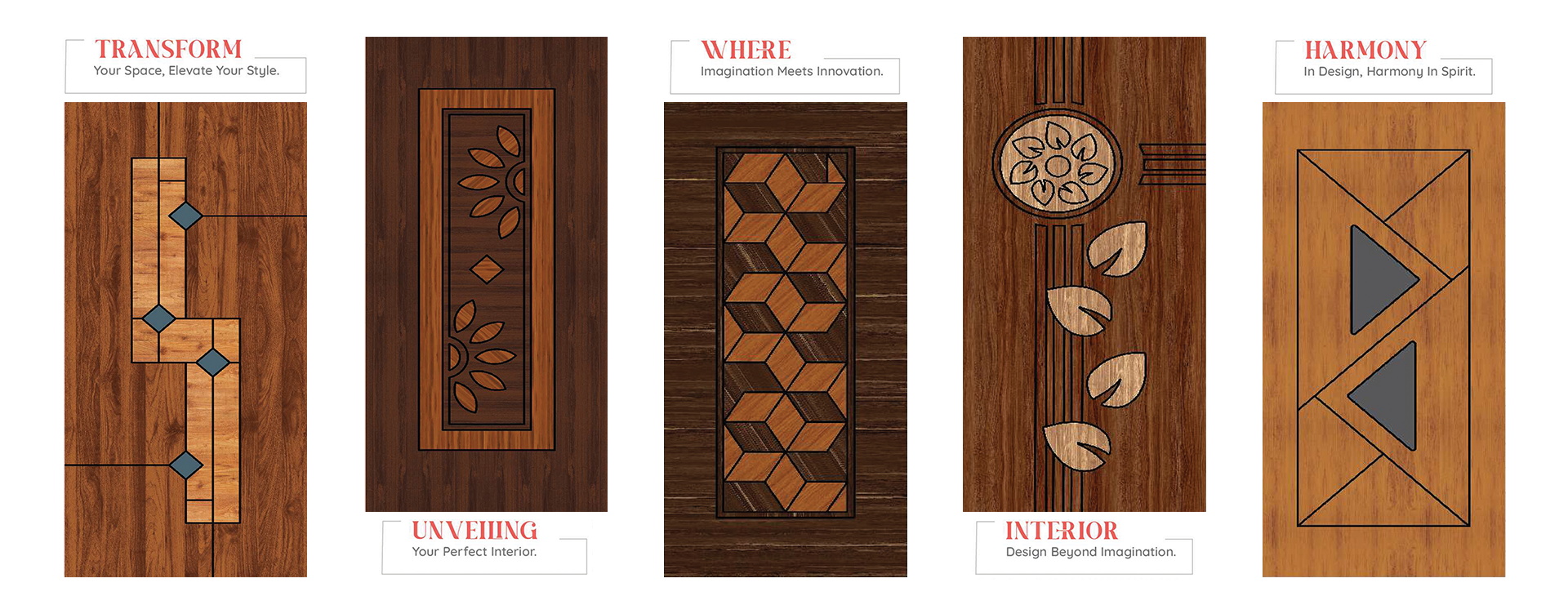

Design Flexibility Without Wood-Related Risk

| Design Capability | Commercial Benefit |

|---|---|

| CNC routing | Premium panel designs (60+ patterns) |

| Digital printing | HD realistic wood grains (100+ designs) |

| Textured finishes | Contemporary & premium appeal |

| Lamination compatibility | Easy interior matching |

This allows distributors to offer high-end aesthetics with zero moisture or termite risk.

Why Importers Prefer WPC Over Wooden Doors ?

| Importer Priority | Wooden Doors | WPC Doors |

|---|---|---|

| Moisture resistance | ❌ | ✅ |

| Termite protection | ❌ | ✅ |

| Batch consistency | ❌ | ✅ |

| Claim risk | High | Low |

| Long-term cost control | Weak | Strong |

| Scalability | Limited | Excellent |

Distributors report 20–30% lower after-sales costs after switching from wooden doors to WPC doors.

Regional Demand Indicators

| Region | Key Driver |

|---|---|

| Middle East | High humidity & termite exposure |

| Africa | Low maintenance & price stability |

| Southeast Asia | Moisture resistance & urban housing |

| Institutional projects | Uniformity & durability |

Read More About GCC’s Building Materials Product Range

In GCC and African markets, WPC doors now account for 50–70% of door volumes in large residential and hospitality projects.

How GCC Supports Importers in WPC Door Sourcing ?

GCC treats WPC doors as a structured export program, supplying doors and frames together,not as isolated SKUs.

GCC supplies export-grade WPC doors to distributors across the Middle East, Africa, and Asia, combining:

| Importer Need | GCC Capability |

|---|---|

| Stable supply | Export-grade, audited production |

| Sizes & designs | Standard sizes + 100+ design options |

| OEM / private label | Full branding support |

| Logistics | Mixed containers with panels & profiles |

| Documentation | Complete customs & export compliance |

Citations & Market References

https://www.grandviewresearch.com/industry-analysis/doors-market

https://www.statista.com/markets/400/topic/481/construction/