Cementitious vs Liquid Waterproofing

Cementitious vs Liquid Waterproofing – Which Performs Better in Middle East? Waterproofing failure in the Middle East is rarely a...

The global demand for wall and floor tiles is surging, propelled by rapid urbanization, architectural innovation, and an increasing focus on interior aesthetics and functionality. The market is projected to reach USD 510 billion by 2030, growing steadily at a CAGR of 5.8% (Statista 2024). Asia leads the manufacturing landscape, with India, China, Vietnam, and Indonesia collectively accounting for over 60% of global tile exports.

Importers and distributors depend on diverse tile sizes and finishes to satisfy increasingly sophisticated design requirements across Europe, the Middle East, North America, and Asia-Pacific. However, sourcing challenges abound — inconsistent sizing, variable surface finishes, and gaps in compliance documentation can disrupt projects, inflate costs, and slow market entry.

Buyer Pain Points: What Importers Struggle With

Tile importers often encounter three recurring issues that impact project reliability and profit margins:

To overcome these issues, buyers must work with exporters who adhere to ISO 13006 / EN 14411 standards and maintain batch-level inspection and calibration data.

Understanding Wall and Floor Tiles: Core Categories

Wall and floor tiles differ in strength, finish, and installation use. Importers must distinguish these during sourcing.

| Category | Surface Finish | Typical Size Range | Applications | Key Export Grades |

|---|---|---|---|---|

| Ceramic Wall Tiles | Glossy, Matt, Satin | 200×300 mm, 300×600 mm | Bathrooms, kitchens, interiors | ISO 10545, EN 14411 |

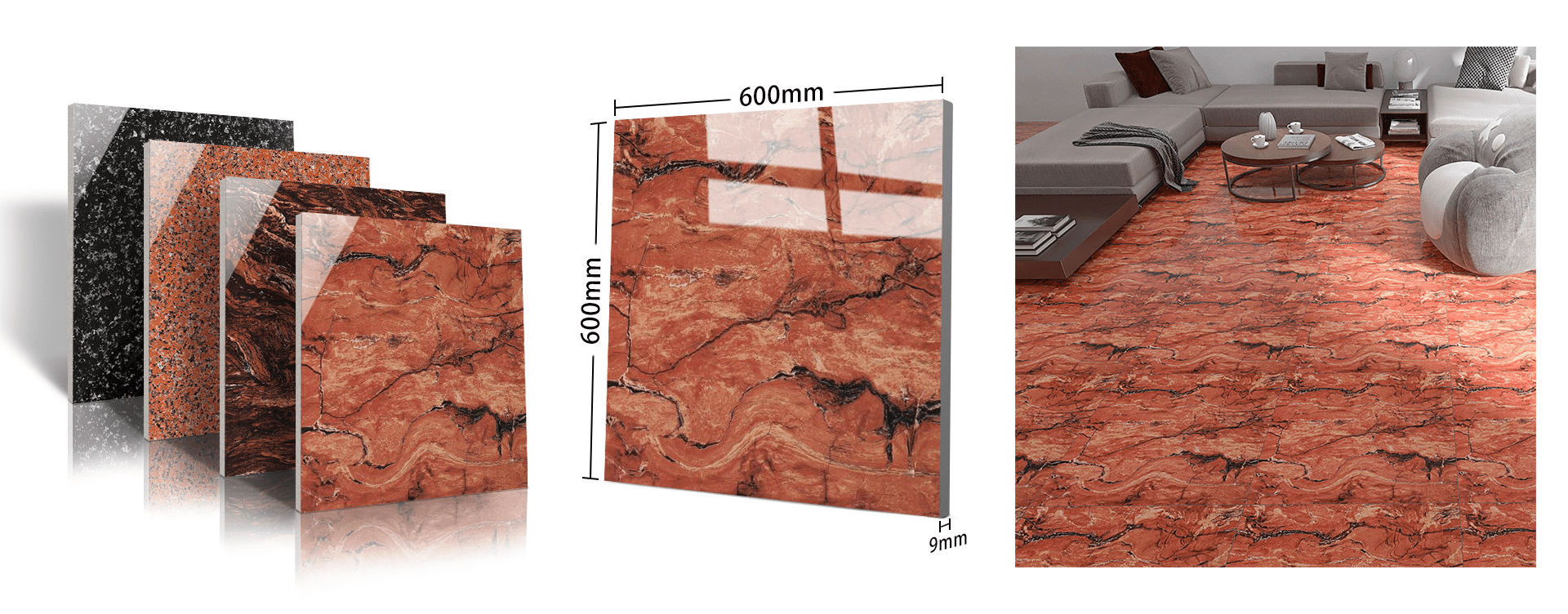

| Vitrified Floor Tiles | Glossy, Matt, Sugar, Carving | 600×600 mm, 800×800 mm | Residential, commercial flooring | ISO 13006, IS 15622 |

| Porcelain Tiles | Polished, Lapato, Rustic | 600×1200 mm, 800×1600 mm | High-traffic zones, malls, facades | EN 14411 BIa, ASTM C373 |

| Full Body & Double Charge Tiles | High-gloss, marble-look | 600×600 mm, 600×1200 mm | Heavy-duty flooring, lobbies | ISO 10545-3, EN ISO 10545-7 |

| Outdoor & Parking Tiles | Anti-skid, rough, textured | 300×300 mm, 400×400 mm | Driveways, exterior areas | R11–R13 Slip Rating, EN 101 |

Read More About GCC’s Tiles Product Range

Global Size and Finish Preferences: Import Trends

| Region | Preferred Sizes (mm) | Popular Finishes | Market Insight (2024) |

|---|---|---|---|

| Middle East & Africa | 600×600 / 800×800 / 600×1200 | Glossy, High-Polish Marble Look | Strong demand for luxurious aesthetic finishes |

| Europe | 300×600 / 600×1200 / 800×1600 | Matt, Textured, Soft Touch | Focus on anti-slip, low-reflective tiles for minimal interiors |

| North America | 600×600 / 750×1500 / 1200×1200 | Polished, Wood Grain, Stone Look | Growth in porcelain slabs & large-format tiles |

| Asia-Pacific | 600×600 / 600×1200 | Glossy, Sugar Finish | Fast-moving retail-grade tiles for mass housing |

| Oceania | 600×1200 / 800×1600 | Matt, Lapato | Demand for premium vitrified and porcelain tiles |

Global data shows a steady shift toward larger-format tiles (600×1200 mm and above) due to easier installation and modern aesthetics. Meanwhile, matt and soft-touch finishes continue to rise across premium interiors.

Read More About GCC’s Granite, Marble & Sandstone Range

Product Portfolio

GCC offers an extensive range of export-grade tiles with complete documentation and certification:

| Product Category | Material / Type | Certifications & Standards | Product Link |

|---|---|---|---|

| Ceramic Wall Tiles | Glazed ceramic, glossy/matt | ISO 10545, EN 14411 | Wall Tiles |

| Vitrified Floor Tiles | Double charge, soluble salt | ISO 13006, IS 15622 | Vitrified Tiles |

| Porcelain Tiles | Polished, rustic, lapato finish | EN 14411 BIa, ASTM C373 | Porcelain Tiles |

| Outdoor/Parking Tiles | Anti-skid, textured | EN 101, DIN 51130 | Outdoor Tiles |

| Tile Accessories (Construction Chemicals) | Spacers, grouts, trims | ISO 9001:2015 | Construction Chemical Materials |

Each batch shipped includes Certificates of Analysis (COA), factory test reports, and standardized packaging ready for retail or project use.

Bridging Challenges with GCC’s Solutions

Inconsistent tile sizes and finishes across batches cause delays in installation, increase returns, and complicate client trust. GCC addresses these through rigorous batch-level quality control, shade matching, and dimensional calibration, ensuring uniformity whether for a single container or multi-SKU shipments.

Our OEM and private-label services empower importers with customized packaging, CE-compliant labeling, and barcoding suited for diverse markets. Export logistics benefit from container consolidation, mixing wall, floor, and outdoor tiles to maximize freight efficiency while maintaining careful batch segregation.

Future Outlook

Market trends point to rising demand for large-format tiles exceeding 600×1200 mm and finishes prioritizing eco-friendliness with low VOC emissions and recycled contents. Automated kiln technologies, digital color management, and robotic polishing lines deployed in India and Vietnam amplify consistency across export batches.

For importers, partnering with GCC means reliable access to cutting-edge tile production with export-grade certification, transparent batch data, and global trade expertise—securing your product quality and timeline.

Explore GCC’s Tile & Building Material Ranges:

| Product Category | Product Link |

|---|---|

| Ceramic Wall Tiles | Ceramic Wall Tiles |

| Vitrified & Porcelain Floor Tiles | Vitrified & Porcelain Floor Tiles |

| Outdoor Tiles & Parking Solutions | Outdoor Tiles & Parking Solutions |

| Construction Adhesives & Materials | Construction Adhesives & Materials |

GCC is your trusted export partner, delivering quality and consistency from manufacturer to market.

Citation:

https://www.grandviewresearch.com/industry-analysis/ceramic-tiles-market

https://www.precedenceresearch.com/ceramic-tiles-market

https://www.iso.org/standard/63406.html

https://standards.iteh.ai/catalog/standards/cen/d33e61b4-2316-4d49-9d5a-5c74cfcf9b3a/en-14411-2016

https://safetydirectamerica.com/germanys-din-51130-slip-test-whats-it-good-for/