Product Details

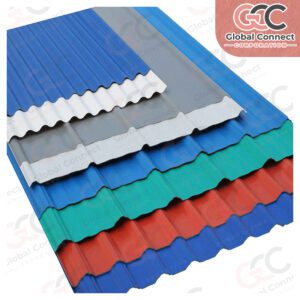

Our Steel range offers a wide spectrum of high-quality products tailored for infrastructure, construction, industrial fabrication, and engineering sectors. Steel Plates are precision-engineered for toughness and dimensional accuracy in demanding environments such as shipbuilding and heavy machinery. Structural Steel sections are optimized for building and bridge construction, providing reliable yield strength and toughness.

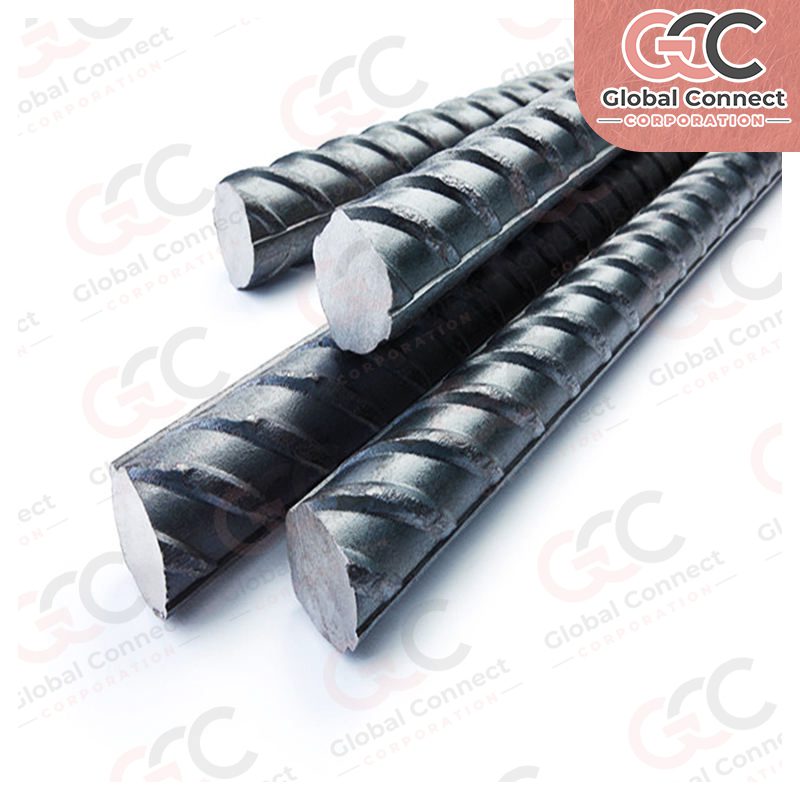

TMT and reinforcement bars meet seismic and load requirements, enhancing concrete bonding and overall structural safety. Stainless Steel products combine corrosion resistance and aesthetics for hygienic and architectural uses. Additionally, alloy and tool steels deliver exceptional performance for automotive, tooling, and industrial equipment. Complementary wire and mesh solutions support fencing, construction binding, and filtration needs with excellent corrosion protection. All products comply with stringent international standards, supported by customization and global logistics capabilities to serve diverse markets.

Product Types & Variants: Steel plates (boiler quality, structural, high tensile, alloy), structural steel sections (angles, beams, channels), TMT & reinforcement bars, stainless steel sheets/coils/pipes, alloy & tool steel, wire products, mesh, and accessories

Material Options: Mild steel, carbon steel, alloy steel, stainless steel (austenitic, ferritic, martensitic), weathering steel, tool steel

Sizes & Configurations: Plates (3–150 mm thickness, widths to 4,000 mm, lengths up to 12,000 mm), structural sections (50–500 mm width), TMT bars (6–40 mm diameter), stainless sheets (0.3–40 mm thickness), wire gauges 16–32 gauge

Performance Specs: High tensile strength (up to 700 MPa), impact and corrosion resistance, weldability, ductility, abrasion resistance

Finish Options: Mill finish, bright, pickled & oiled, epoxy-coated, painted, shot-blasted, polished, brushed, galvanized

Quality & Certifications: IS, ASTM, EN, JIS, DIN, AISI, ISO 9001:2015

Customization Options: Custom lengths, cut-to-size, heat treatments, surface treatments, packaging, branded solutions

Applications: Construction, shipbuilding, heavy machinery, automotive, infrastructure, marine, food processing, pharmaceutical, fencing

MOQ & Lead Time: MOQ varies from 1 MT upwards; lead time 1–8 weeks depending on product and specification