Product Details

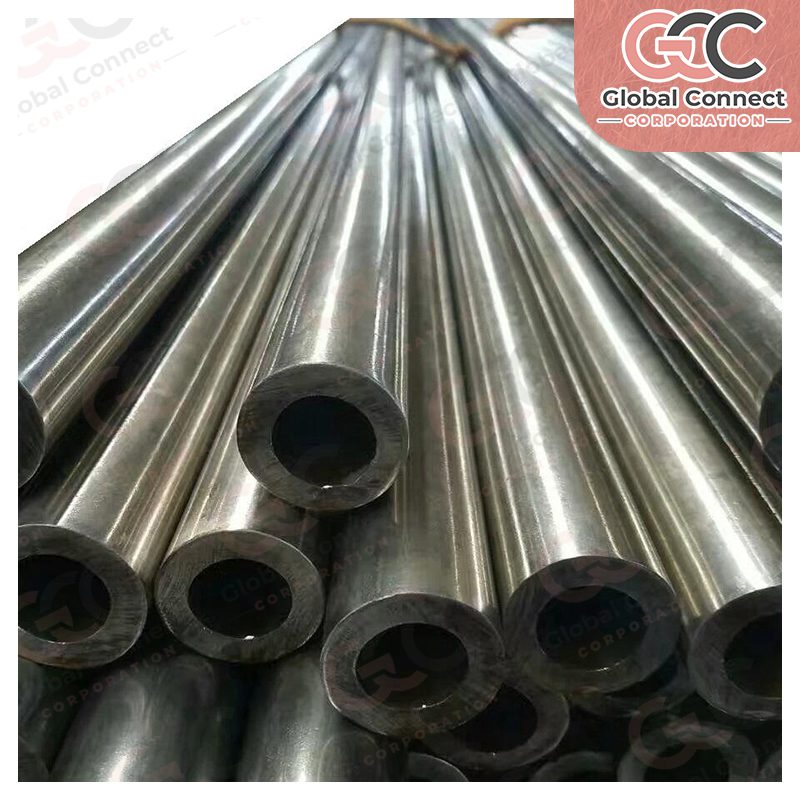

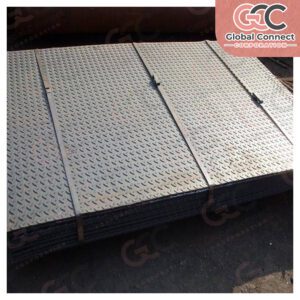

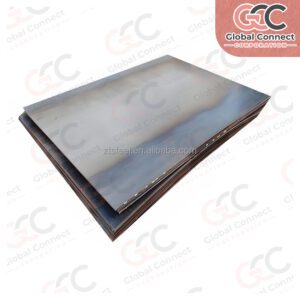

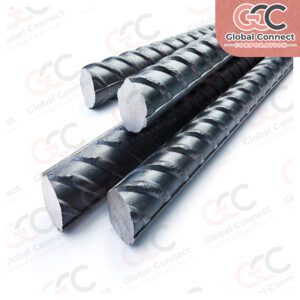

Our alloy and tool steels are precisely engineered to deliver superior mechanical strength, wear resistance, and durability essential for industrial tooling and heavy machinery. Heat-treated and processed with accuracy, these steels satisfy the stringent requirements of automotive, aerospace, and manufacturing industries. Custom hardening and tempering solutions enhance performance and extend component lifespan.

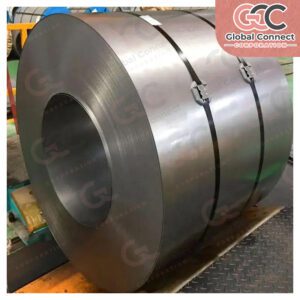

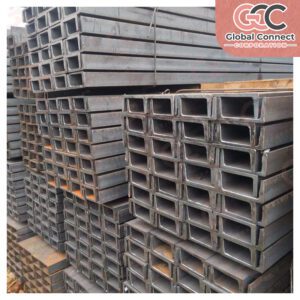

Product Types: Alloy steels for high strength and wear resistance; tool steels for cutting, molding, and forming tools

Material Options: Alloy grades such as 20MnMo, 40Cr, 42CrMo, EN 24; tool steel grades including D2, H13, O1, A2

Sizes: Bars, plates, rods, flat and round forms; custom heat treatments available

Performance: High tensile strength, excellent toughness, wear and thermal resistance, machinable

Finish Options: Hot rolled, cold drawn, ground, hardened, tempered

Certifications: IS 2062, ASTM A29, EN 10083, ISO 4957, ISO 9001

Applications: Automotive parts, heavy machinery, molds, dies, cutting tools, industrial equipment

Special Features: Custom heat treatment, superior mechanical properties, dimensional stability

Packaging: Bundled, rust-preventive treatment, export-grade crates available

MOQ: 1 MT per size and grade

Lead Time: 3–8 weeks depending on specification and treatment