Product Details

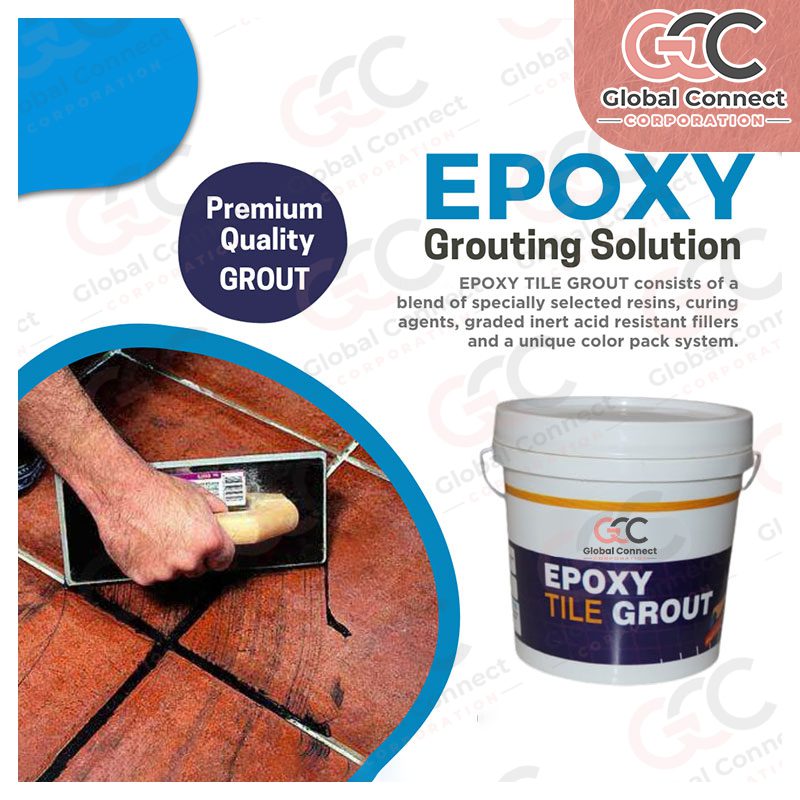

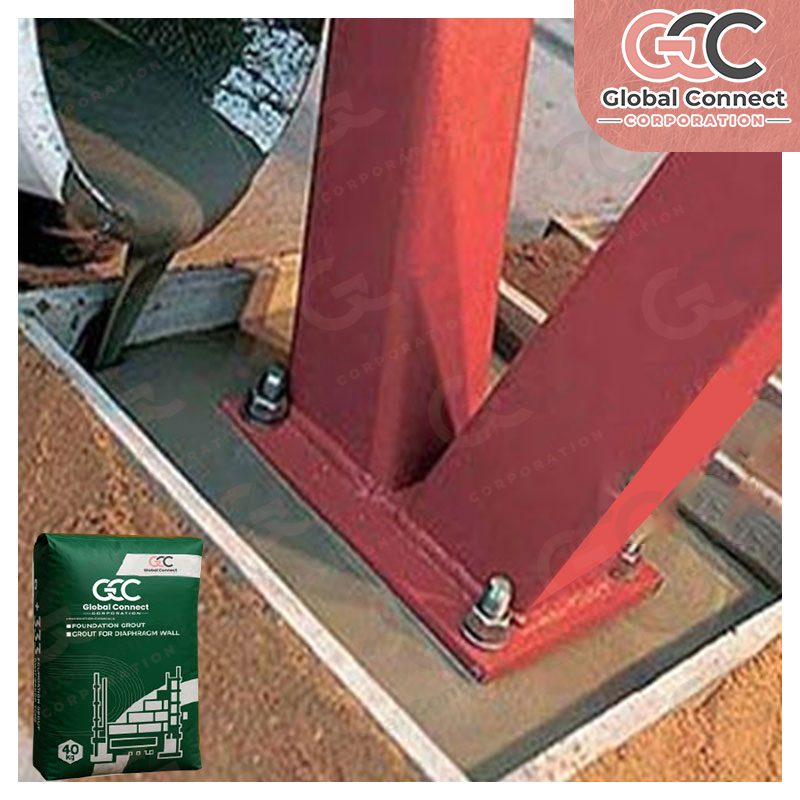

Our Grouts & Anchoring Compounds range delivers reliable, high-performance solutions critical for structural integrity and construction efficiency. Cementitious grouts provide high strength, excellent flow, and non-shrink properties ideal for filling voids beneath heavy machinery and structural elements. Epoxy grouts and anchoring compounds offer outstanding chemical and mechanical resistance, ensuring durable bonds in demanding environments such as machine bases, anchor bolt fixing, and industrial flooring.

Polyester and hybrid systems provide rapid curing and robust anchorage even on damp or difficult substrates. Precision and flowable grouts enable accurate load transfer and void filling, optimizing stability for civil, industrial, and commercial projects. Produced under stringent international standards, these products offer unmatched quality and performance to meet diverse construction needs.

Product Types & Variants: Cementitious grouts, epoxy grouts & anchoring compounds, polyester & hybrid anchoring systems, precision & flowable grouts

Material Options: High-strength Portland cement, epoxy resin and hardener kits, polyester resin with hardener, polymer-modified cementitious formulations

Sizes & Configurations: Available in powders (25kg, 40kg bags), pre-measured epoxy kits (1.5kg to 45kg), cartridges/capsules, and bulk packs

Performance Specs: Non-shrink, high compressive strength (≥40 MPa typical), rapid to standard setting times, chemical and water resistant, high flowability, vibration and impact resistant

Compatibility: Suitable for concrete, steel base plates, masonry, precast elements, machine foundations, bridge bearings, rebar anchoring, crack injection, slab stabilization

Finish / Colour Options: Available in multiple grout colors and epoxy variants; adhered well to various substrates with excellent durability

Quality & Certifications: Certified as per IS, ASTM, EN, and ISO 9001:2015 standards

Customization Options: Various pack sizes, formulations tailored for project requirements, packaging options

Applications: Structural grouting, machine base support, anchor bolt fixing, retrofit installations, precast panel connections, flooring repairs, bridge supports