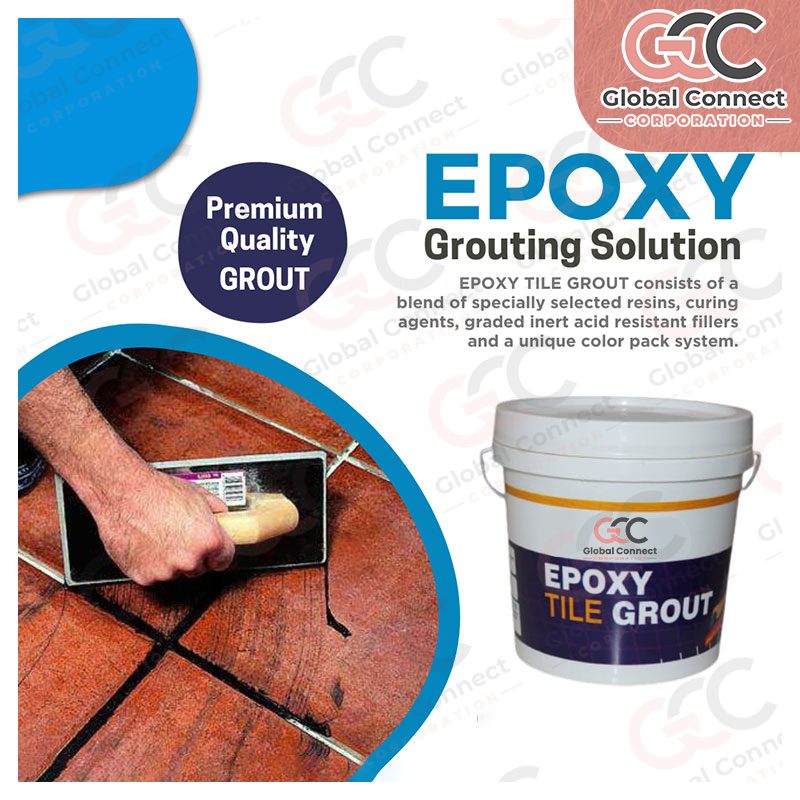

Product Details

Epoxy grouts and anchoring compounds are designed for demanding industrial and construction applications requiring exceptional strength, durability, and chemical resistance. These two-component systems form strong, secure bonds for structural elements, supporting heavy loads and dynamic stresses while resisting corrosion and moisture. Their high flowability and non-shrink properties ensure void-free gap filling, ideal for machine grouting, baseplates, rebar anchoring, and critical infrastructure repairs.

Product Types: Two-component epoxy grout and anchoring compounds (e.g., D Fix Crack & Fix, D Fix Diamond)

Materials: Pre-measured resin and hardener kits for precise mixing

Performance: Superior adhesion, non-shrink; high compressive (>70 MPa) and flexural strength; excellent chemical and moisture resistance

Compatibility: Suitable for machine bases, anchor bolt fixing, structural grouting, rebar anchoring, bridge and column connections

Special Features: Solvent-free; rapid and medium curing options; vibration and dynamic load resistant; waterproof and corrosion resistant

Packaging: Kits in 1.5kg, 7.5kg, 45kg sizes

Applications: Heavy machinery foundations, precast panel joints, steel and concrete anchoring, crack injection, structural grouting

Mixing Ratios: Pre-measured components for consistent performance

Application Methods: Brush, roller, trowel, injection

Shelf Life: 12–24 months sealed under dry storage