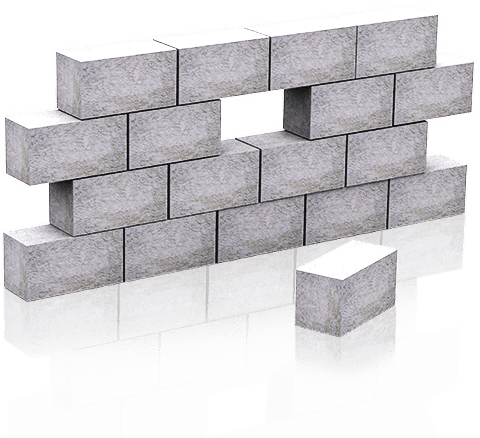

Product Details

AAC (Autoclaved Aerated Concrete) blocks are lightweight, energy-efficient construction materials offering excellent thermal insulation and fire resistance. Manufactured under high-pressure steam curing, they feature precision-cut edges for easy installation and reduced mortar use.

Their porous structure also provides superior soundproofing. Widely used in residential and commercial buildings, AAC blocks are recognized globally for sustainability and perform well in varied climates by reducing structural load and HVAC energy consumption.

Product Types: AAC blocks with lightweight, high thermal insulation, and fire resistance

Material Options: Cement, lime, sand, water, and aluminum powder cured under autoclave steam

Sizes: Standard 600x200x100/150/200 mm; custom sizes available

Performance: Dry density 550–650 kg/m³; compressive strength 3–5 MPa; thermal conductivity 0.15–0.25 W/m·K; excellent sound insulation and fire rating

Finish Options: Smooth, precision-cut edges for easy laying and finishing

Certifications: IS 2185 Part 3, EN 771-4, ASTM E119 (fire rating)

Applications: Load-bearing/non-load-bearing walls, infill panels, multi-story and high-rise buildings, eco-friendly construction

Special Features: Lightweight for reduced structural load; energy-saving thermal insulation; easy cutting/installation; recycled content possible

Packaging: Plastic-wrapped pallets for export protection

MOQ: 1 full container load

Lead Time: 2–4 weeks