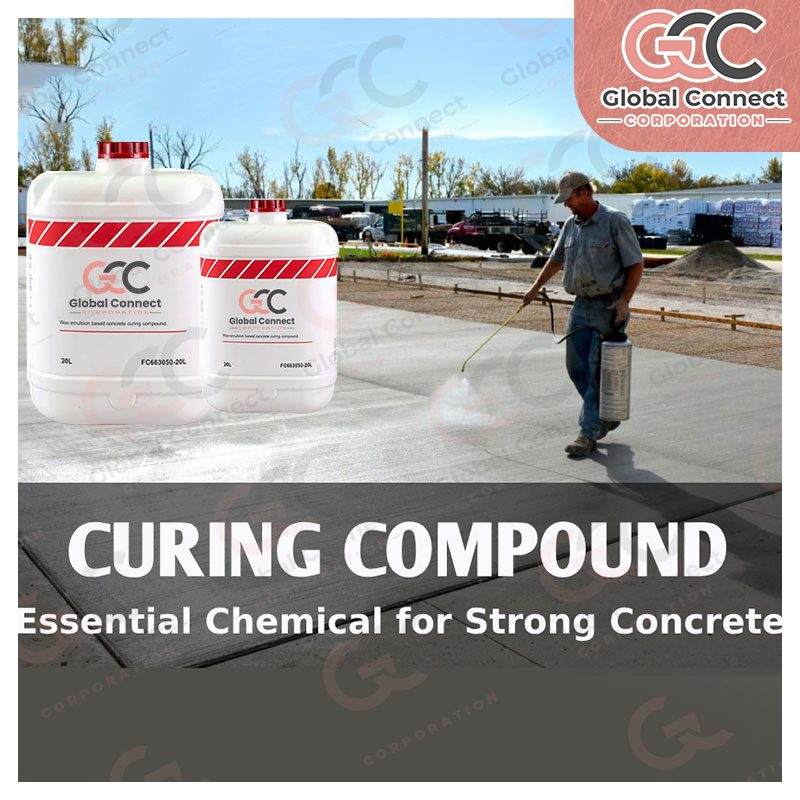

Product Details

Concrete curing compounds are designed to optimize cement hydration by preventing excessive moisture loss in freshly placed concrete, thereby enhancing strength, reducing surface cracking, and improving durability. These ready-to-use liquids offer easy spray-on application and quick drying, making them essential for all concrete finishing processes, particularly where traditional water curing is challenging.

Product Types: Water-based and solvent-based curing compounds including acrylic, resin, and wax emulsions

Materials: Ready-to-use liquids suitable for spray or brush application

Performance: Reduces moisture loss, promotes cement hydration, improves concrete strength and durability

Compatibility: Suitable for all concrete surfaces such as pavements, industrial floors, bridge decks, precast units

Special Features: Forms a protective membrane; available in white pigmented, clear, and colored variants; helps reduce thermal cracking

Packaging: Available in 20L, 50L, 200L drums and 1000L IBCs

Application Areas: Freshly finished concrete, exposed slabs, highways, airports, large infrastructure projects

Application Methods: Sprayer, roller, or brush with quick drying for fast site turnover

Standards Compliance: IS 9103, ASTM C309, EN 934-3

Shelf Life: Typically 12–18 months unopened, stored in cool, dry conditions