Product Details

Polysulphide sealants provide exceptional durability and flexibility for demanding joint sealing where chemical exposure and high movement are present. Their long curing times and robust mechanical properties ensure tight, waterproof seals in infrastructure, aviation, industrial, and marine projects. These sealants accommodate significant expansion and contraction without cracking or debonding, delivering reliable weatherproof protection.

Product Types: Two-component polysulphide sealants for heavy-duty, long-lasting joint sealing

Materials: Pre-measured resin and hardener kits for precise mixing and consistent performance

Performance: Exceptional elasticity; excellent chemical resistance; UV stable; waterproof

Compatibility: Ideal for expansion and structural joints in airports, warehouses, industrial floors, bridges, marine environments

Special Features: Rubber-like seals resistant to aging, extreme temperatures, water immersion, aggressive chemicals

Packaging: Typically 4kg kits and larger sizes for large projects

Application Areas: Airport runways, highways, bridges, warehouses, tank joints, marine structures

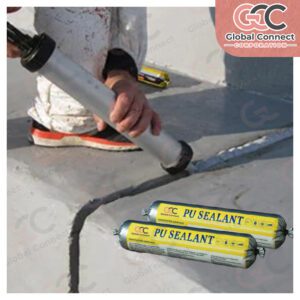

Application Methods: Applied with static mixing guns, trowels, or specialized tools

Standards Compliance: ASTM C920, EN 14188, IS specifications

Shelf Life: About 12 months when stored sealed in cool, dry conditions